Eraring Power Station

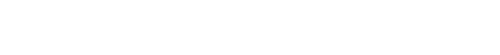

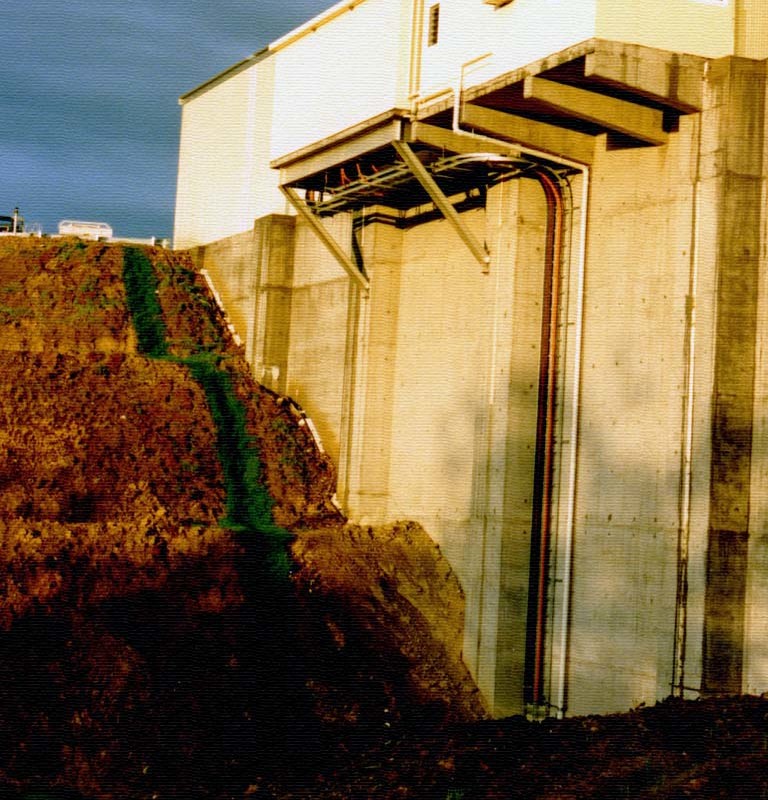

The hopper system consists of eight individual storage pods. Each pod is independent from the others to accommodate potential future mine subsidence. The pods are separated by a panel of polystyrene. The polystyrene is designed to crush and allow the pods to rotate in the event of subsidence taking place. The side walls (below ground level) are also lined with polystyrene and the crushing pressure of the polystyrene is used to control any increase in wall pressure due to the predicted subsidence.

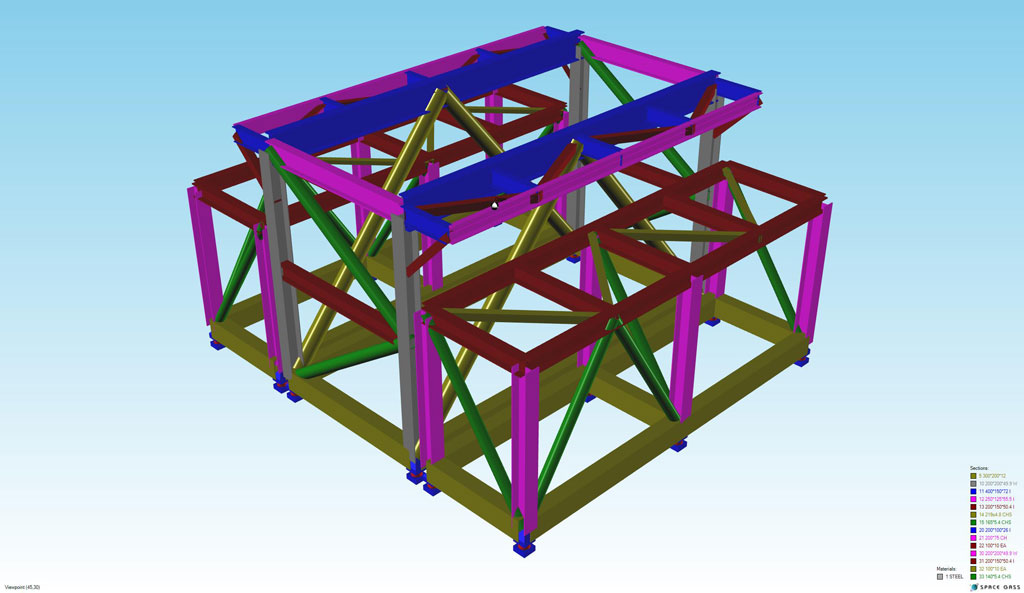

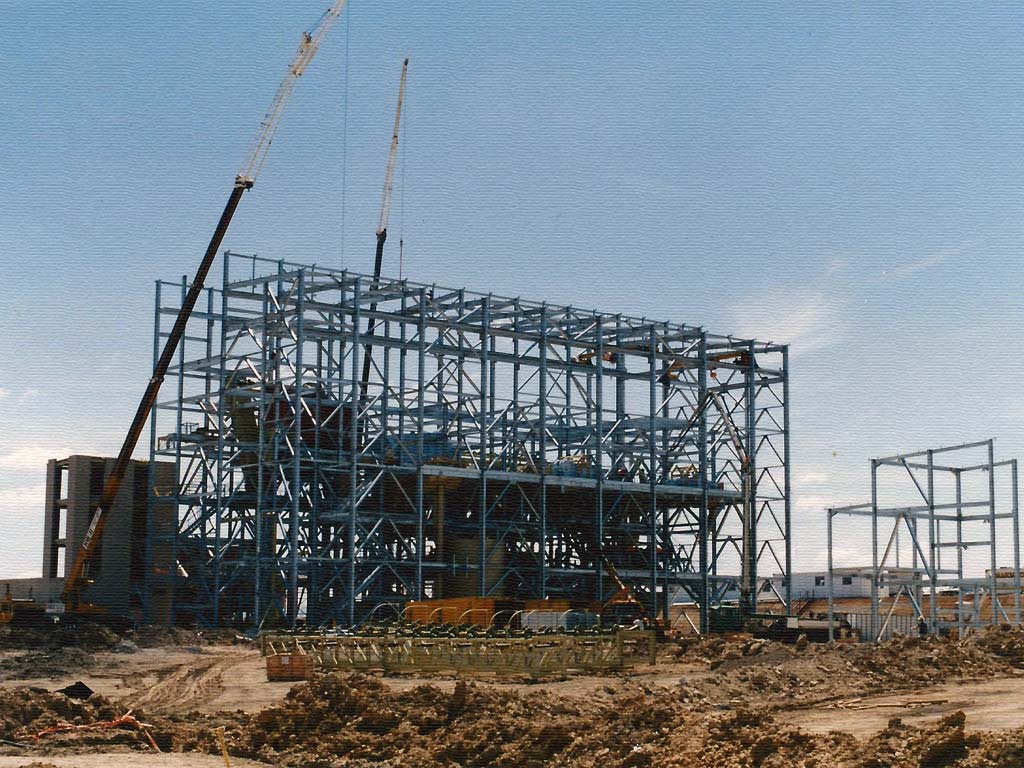

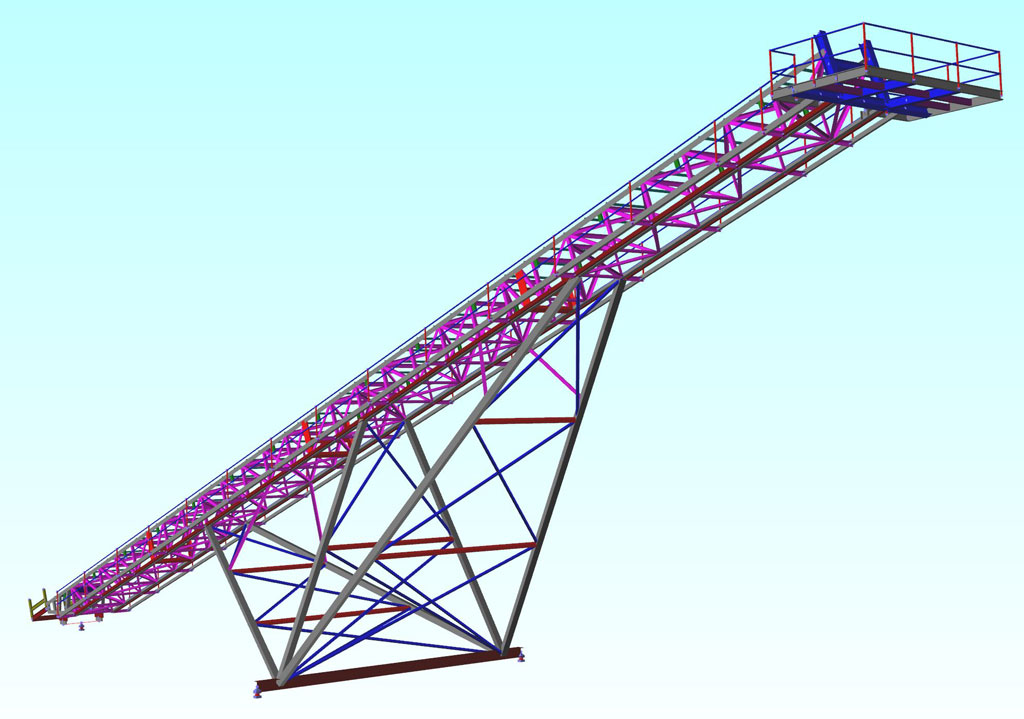

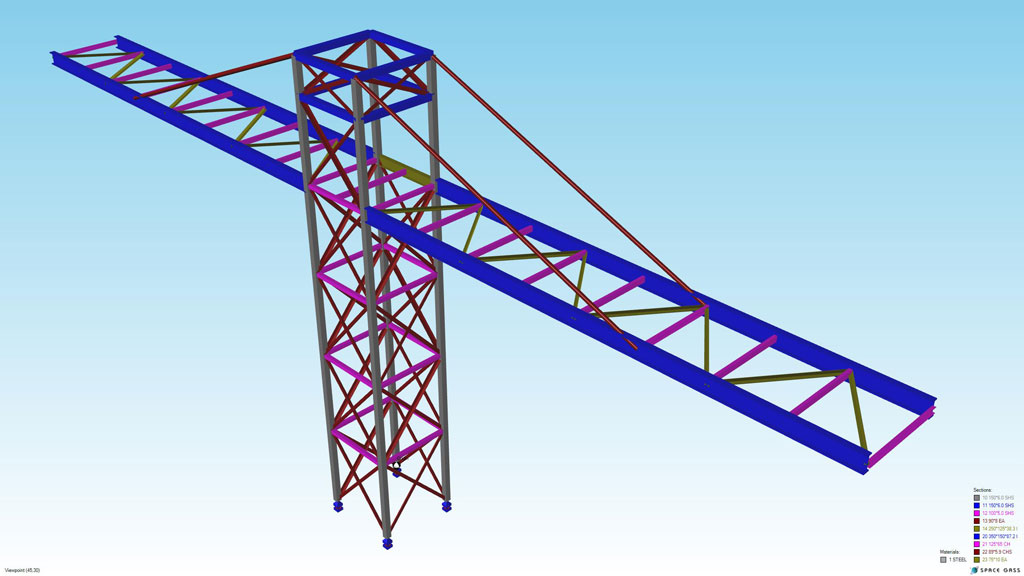

Sitting on top of and supported on the hoppers is the train unloading station. Trains travel across the hoppers discharging their coal into the hoppers via bottom dump wagons. The hoppers are covered with a lightweight portal frame structure, providing a dry working area and also preventing rainwater from entering the hoppers. The bottom of the hoppers is profiled to allow the coal to be discharged via vibrating feeders onto a conveyor that feeds the coal into the power station some 2km away. The whole structure has been designed so that the system can be repaired and realigned after a major subsidence event, ensuring minimal downtime and disruption to the supply system.

Client: Ulan Coal/John Holland