The feeders draw coal from eight hoppers which are situated below the train unloading station.

Gravel Plant Emu Plains

Cantilevered Stockpile Feed Conveyor and Reclaim Tunnel and Conveyor.

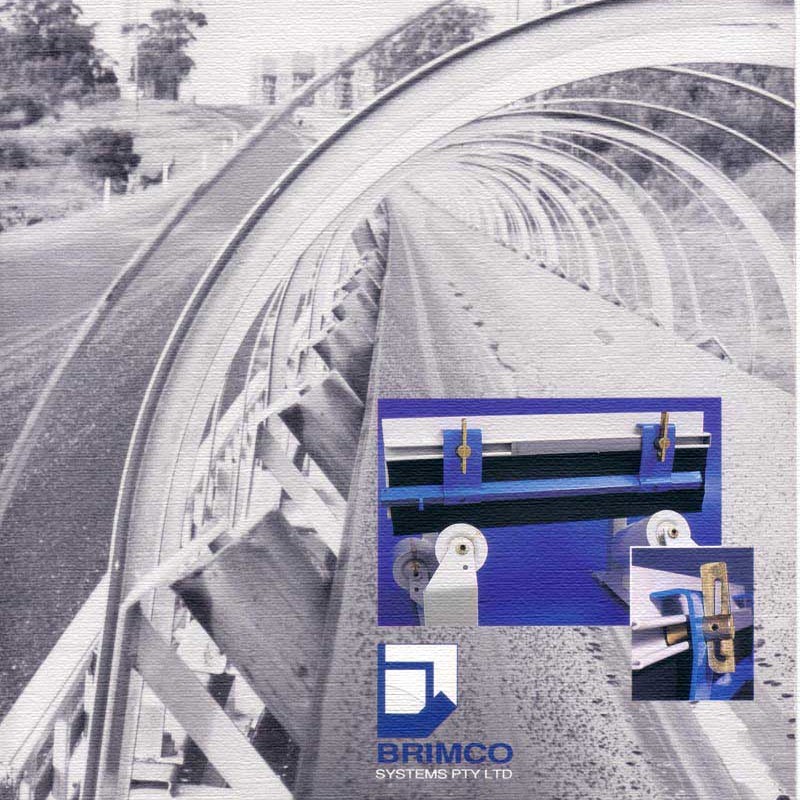

New Screen and Support Structure.

Camberwell Coal – New Screen and Support Structure.

Coal Washery – Screen Floor Retrofit

Coal Washery Screen Floor Retro Installation of additional Vibrating screen at Camberwell Coal Washery NSW.

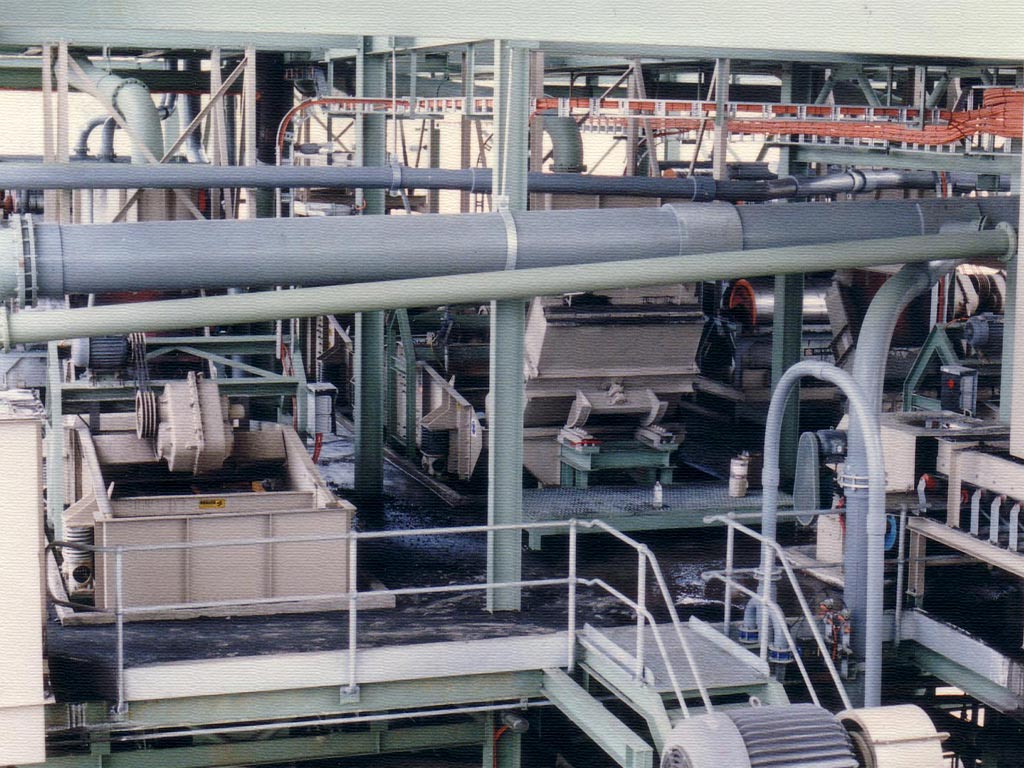

Patented Belt Conveyor Skirt Clamp

This quick release skirt and clamp system was developed, patented, marketed and distributed Brimco Systems Pty Ltd a subsidiary company. The patent rights were eventually sold to a major mining component manufacturer.

CAMBERWELL COAL MINE

The Camberwell Coal Washing Plant is located in the Hunter valley Region of NSW. Close Consultants provided all structural designs for the project. This included ROM facility, conveyors, wash plant, control-room, storage bins, skyline conveyor, reclaim tunnel and stacker reclaimer foundations . The product reclaim tunnel delivers coal to the train loading station.

Screen support structure

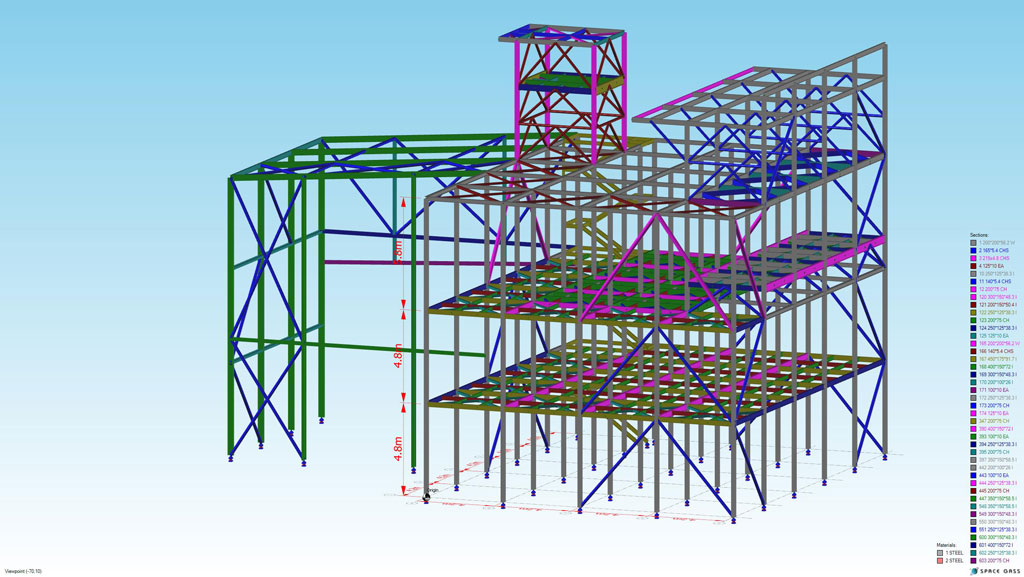

SGASS Model for Static and Dynamic Analysis.

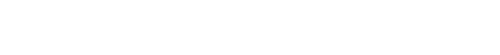

Coal Washery

The existing screen (bottom right hand corner) was providing insufficient capacity. An additional screen, support structure and foundations have been added to improve and increase the material flow, removing a bottleneck in the plant . The photograph shows the catch-tray being lowered into position prior to installing the new screen

Industrial Garnet Processing Plant

The process plant is based upon a modular format and design with the capacity to be disassembled and relocated at some future time.

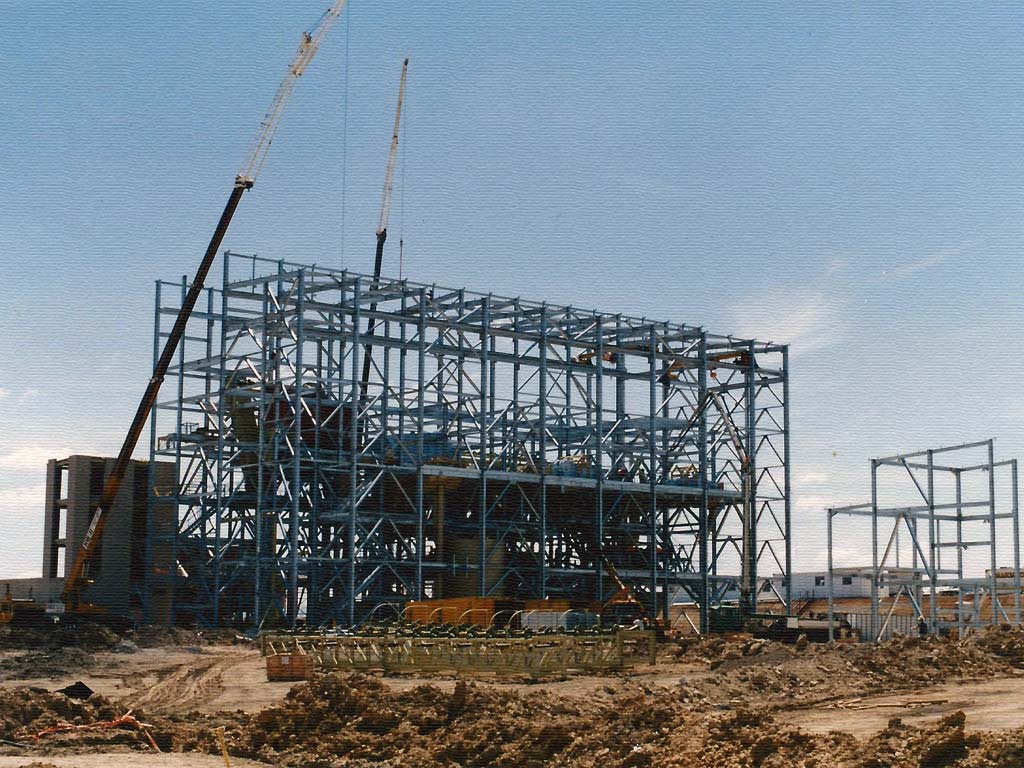

Screen House Under Construction

Braced Steel, Screen House Under Construction at Camberwell Coal, NSW.